Whether you are running a large quarry or a contracting business, Dinghao is your reliable partner.

Our equipment and accessories have been tested through decades of crushing, screening and material transportation experiences, and are all designed to be extremely durable.

With the most extensive customer service and support in the industry, we help you elevate your business to a whole new level. Contact us today!

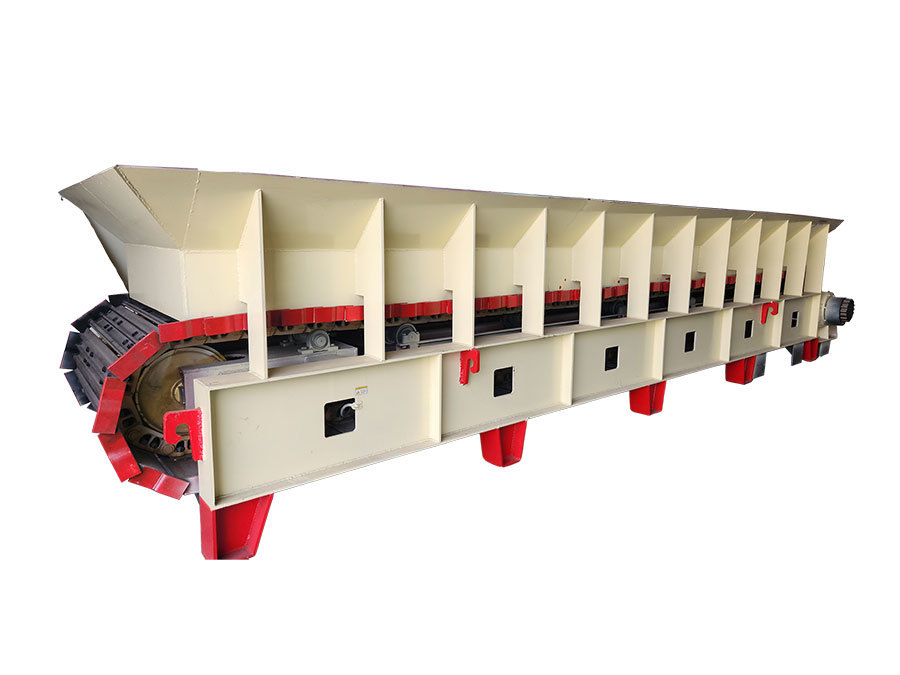

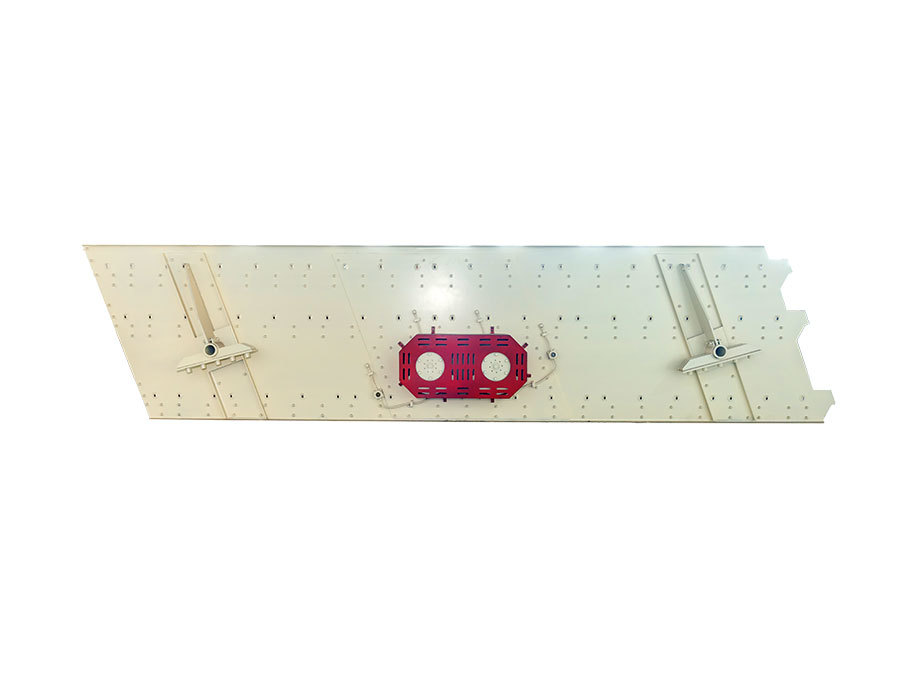

Product Introduction: The feeder is a new type of feeder independently developed and designed by our company based on years of experience in design, production, sales, and service in the mining industry, combined with the development of modern industrial technology and extensive absorption of foreign technology. It is mainly used for continuous and uniform feeding before crushers, capable of evenly, timely, and continuously conveying block and granular materials to crushing machinery. It features a compact structure and strong impact resistance, greatly optimizing the particle size of materials entering the crusher, improving crusher capacity, and reducing energy consumption. It can meet harsh initial feeding conditions such as high bunker pressure, heavy load, and large impact. It is a highly efficient material supply device. Application Range: Widely used in crushing and screening combined equipment in industries such as sand and gravel aggregates, metallurgy, mining, coal mining, mineral processing, cement, construction, building materials, chemical industry, abrasives, refractory materials, and ceramics. Applicable Materials: River pebbles, cobblestones, iron ore, marble, dolomite, coal gangue, quartz, barite, granite, diabase, basalt, iron ore, gold ore, feldspar, silica, calcite, limestone, talc, gypsum, bentonite, and other ores, rocks, and slag materials.

Product Introduction: The feeder is a new type of feeder independently developed and designed by our company based on years of experience in design, production, sales, and service in the mining industry, combined with the development of modern industrial technology and extensive absorption of foreign technology. It is mainly used for continuous and uniform feeding before crushers, capable of evenly, timely, and continuously conveying block and granular materials to crushing machinery. It features a compact structure and strong impact resistance, greatly optimizing the particle size of materials entering the crusher, improving crusher capacity, and reducing energy consumption. It can meet harsh initial feeding conditions such as high silo pressure, heavy load, and large impact. It is a highly efficient material supply device. Application Range: Widely used in crushing and screening combined equipment in industries such as sand and gravel aggregates, metallurgy, mining, coal mining, mineral processing, cement, construction, building materials, chemical industry, abrasives, refractory materials, and ceramics. Applicable Materials: River pebbles, cobblestones, iron ore, marble, dolomite, coal gangue, quartz, barite, granite, diabase, basalt, iron ore, gold ore, feldspar, silica, calcite, limestone, talc, gypsum, bentonite, and other ores, rocks, and slag materials.

Product Introduction: The feeder is a new type of feeder independently developed and designed by our company based on years of experience in design, production, sales, and service in the mining industry, combined with the development of modern industrial technology and extensive absorption of foreign technology. It is mainly used for continuous and uniform feeding before crushers, capable of evenly, timely, and continuously conveying block and granular materials to crushing machinery. It features a compact structure and strong impact resistance, greatly optimizing the particle size of materials entering the crusher, improving crusher capacity, and reducing energy consumption. It can meet harsh initial feeding conditions such as high silo pressure, heavy load, and large impact. It is a highly efficient material supply device. Application Range: Widely used in crushing and screening combined equipment in industries such as sand and gravel aggregates, metallurgy, mining, coal mining, mineral processing, cement, construction, building materials, chemical industry, abrasives, refractory materials, and ceramics. Applicable Materials: River pebbles, cobblestones, iron ore, marble, dolomite, coal gangue, quartz, barite, granite, diabase, basalt, iron ore, gold ore, feldspar, silica, calcite, limestone, talc, gypsum, bentonite, and other ores, rocks, and slag materials.

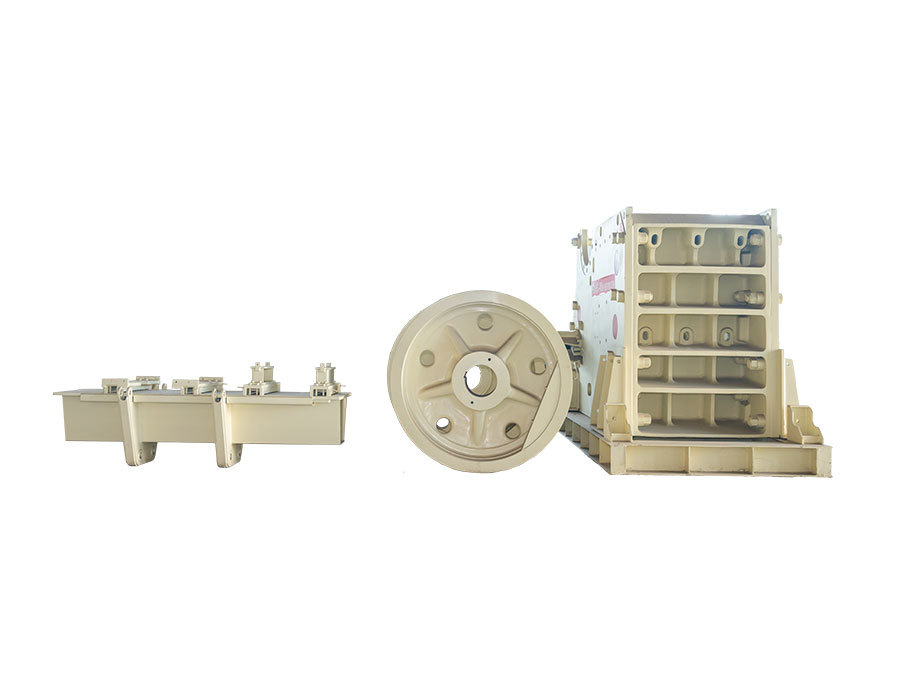

DHC-96 European Version Jaw Crusher

Product Introduction: The European version jaw crusher is a new type of European jaw crusher developed by our company based on the introduction and absorption of foreign jaw crusher technology, combined with decades of accumulated jaw crusher design concepts and technology. It is optimized and manufactured from multiple aspects including structure, material selection, process, and assembly. It features a unique structure and superior performance, making it an ideal equipment for coarse crushing of hard and highly abrasive ores and rocks. It has specially designed features such as a detachable, weld-free frame structure, optimized cavity structure, double wedge block adjustment device, selected raw materials and components, elastic limit shock absorption device, and integrated motor base. It offers high crushing efficiency, low investment cost, long service life, and stability, thereby meeting different working conditions, reducing the tonnage cost of material crushing, and satisfying customer expectations. The European version jaw crusher is a crushing equipment favored by the market. Application Range: Widely used in mining, sand and gravel yards, cement plants, road construction, metallurgy, chemical industry, construction, refractory materials, ceramics, and other industrial sectors. Also applicable to sand and gravel yards, mining, coal mining, concrete mixing plants, dry mortar, power plant desulfurization, quartz sand, etc. Applicable Materials: Granite, marble, pebble, dolomite, limestone, cobblestone, gold ore, basalt, quartz, river pebble, iron ore, diabase, iron ore, gold ore, copper ore, ore, rock, slag, etc.

DHC-125 European Version Jaw Crusher

Product Introduction: The European version jaw crusher is a new type of European jaw crusher developed by our company based on the introduction and absorption of foreign jaw crusher technology, combined with decades of accumulated jaw crusher design concepts and technology. It is optimized and manufactured from multiple aspects including structure, material selection, process, and assembly. It features a unique structure and superior performance, making it an excellent choice for coarse crushing of hard and highly abrasive ores and rocks. It has specially designed features such as a detachable, weld-free frame, optimized cavity structure, double wedge adjustment device, selected raw materials and components, elastic limit shock absorption device, and integrated motor base. It offers high crushing efficiency, low investment cost, long service life, and stability, meeting different working conditions. It reduces the tonnage cost of material crushing, meets customer expectations, and fills market gaps. The European version jaw crusher is a crushing equipment highly favored by the market. Application Range: Widely used in mining, sand and gravel plants, cement plants, road construction, metallurgy, chemical industry, construction, refractory materials, ceramics, and other industrial sectors. Also suitable for sand and gravel yards, mining, coal mining, concrete mixing plants, dry mortar, power plant desulfurization, quartz sand, etc. Applicable Materials: Granite, marble, pebble, dolomite, limestone, cobblestone, gold ore, basalt, quartz, river pebble, iron ore, diabase, iron ore, gold ore, copper ore, ore, rock, slag, etc.

DHC-145 European Version Jaw Crusher

Product Introduction: The European version jaw crusher is a new type of European jaw crusher developed by our company based on the introduction and absorption of foreign jaw crusher technology, combined with decades of accumulated jaw crusher design concepts and technology. It is optimized and manufactured from multiple aspects including structure, material selection, process, and assembly. It features a unique structure and superior performance, making it an ideal equipment for coarse crushing of various hard and highly abrasive ores and rocks. It has specially designed features such as a detachable, weld-free frame structure, optimized cavity structure, double wedge adjustment device, selected raw materials and components, elastic limit shock absorption device, and integrated motor base. It offers high crushing efficiency, low investment cost, long service life, and stability, thereby meeting different working conditions. It reduces the tonnage cost of material crushing, meets customer expectations, and fills market gaps. The European version jaw crusher is a crushing equipment highly favored by the market. Application Range: Widely used in mining, sand and gravel yards, cement plants, road construction, metallurgy, chemical industry, construction, refractory materials, ceramics, and other industrial sectors. Also applicable to sand and gravel yards, mining, coal mining, concrete mixing plants, dry mortar, power plant desulfurization, quartz sand, etc. Applicable Materials: Granite, marble, pebble, dolomite, limestone, cobblestone, gold ore, basalt, quartz, river pebble, iron ore, diabase, iron ore, gold ore, copper ore, ore, rock, slag, etc.

DHC-100 European Version Jaw Crusher

Product Introduction: The European version jaw crusher is a new type of European jaw crusher developed by our company based on the introduction and absorption of foreign jaw crusher technology, combined with decades of accumulated jaw crusher design concepts and technology. It is optimized and manufactured from multiple aspects including structure, material selection, process, and assembly. It features a unique structure and superior performance, making it an excellent choice for coarse crushing of hard and highly abrasive ores and rocks. It has specially designed features such as a detachable, weld-free frame structure, optimized cavity structure, double wedge adjustment device, selected raw materials and components, elastic limit shock absorption device, and integrated motor base. It offers high crushing efficiency, low investment cost, long service life, and stability, meeting different working conditions. It reduces the tonnage cost of material crushing, meets customer expectations, and fills market gaps. The European version jaw crusher is a crushing equipment highly favored by the market. Application Range: Widely used in mining, sand and gravel plants, cement plants, road construction, metallurgy, chemical industry, construction, refractory materials, ceramics, and other industrial sectors. Also suitable for sand and gravel yards, mining, coal mining, concrete mixing plants, dry mortar, power plant desulfurization, quartz sand, etc. Applicable Materials: Granite, marble, pebble, dolomite, limestone, cobblestone, gold ore, basalt, quartz, river pebble, iron ore, diabase, iron ore, gold ore, copper ore, ore, rock, slag, etc.

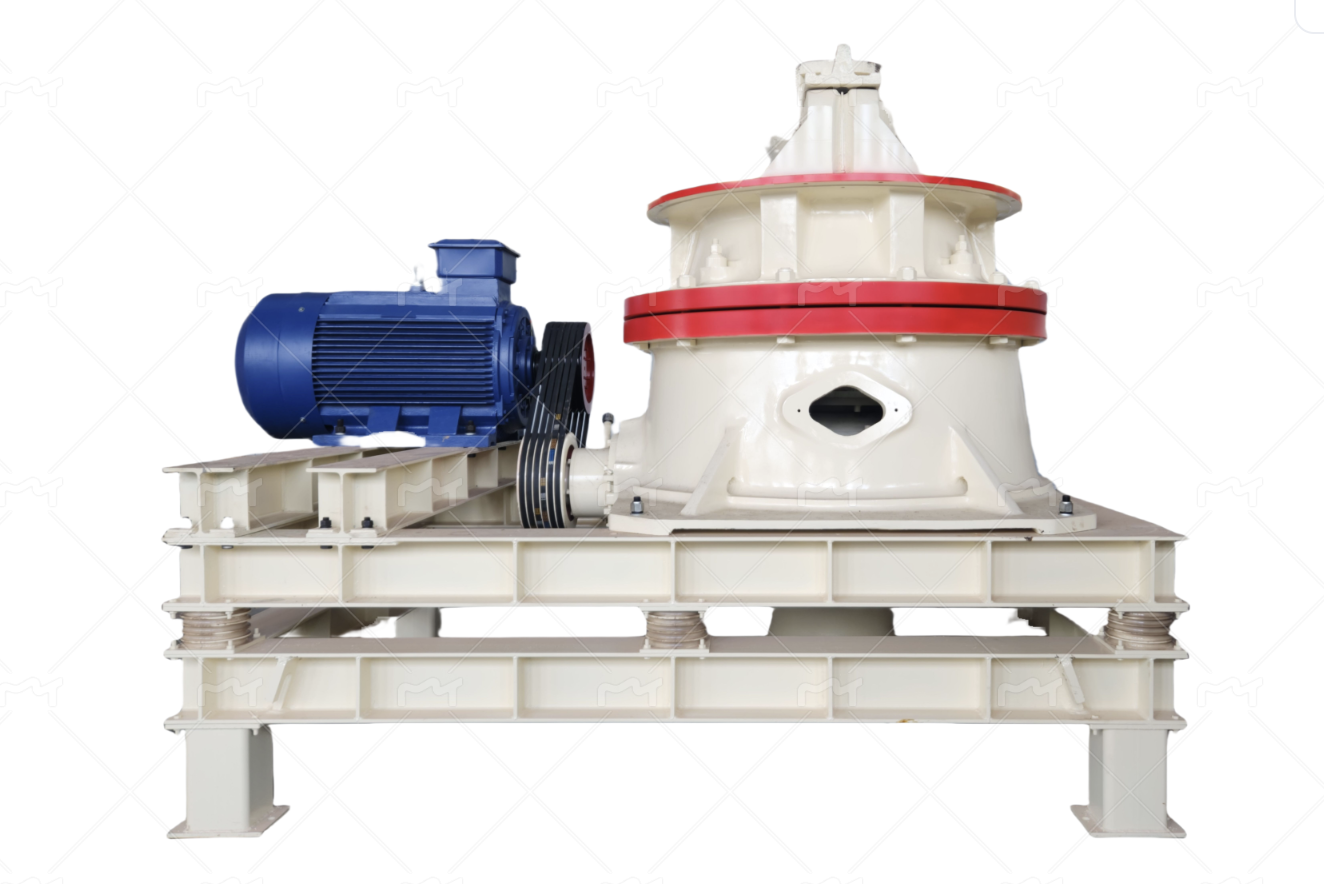

DHGP330S Single-cylinder Hydraulic Cone Crusher

Product Introduction: The single-cylinder hydraulic cone crusher is a high-capacity single-cylinder hydraulic cone crusher optimized and designed by our company based on the introduction and absorption of European and American technologies. This cone crusher features a larger eccentric distance, increased speed, and a cavity design with a higher crushing ratio. It integrates mechanical, hydraulic, electrical, automation, and intelligent control technologies, making it widely applicable for fine, medium, and coarse crushing operations in industries such as metal and non-metallic minerals, cement, sand and gravel, and metallurgy. It boasts advantages such as high crushing efficiency, low production cost, easy maintenance and adjustment, and excellent crushed product particle shape. Application Range: Mainly used for crushing raw materials in metallurgy, mining, construction, chemical, and silicate industries. It can be installed on concrete or steel structure foundations and is suitable for fixed or mobile setups. Applicable for large, medium, and small sand and gravel and ore processing enterprises, such as sand and gravel yards, mining operations, coal mining, concrete mixing plants, dry mortar, power plant desulfurization, quartz sand, and other secondary, tertiary, or quaternary crushing of ores, rocks, or rock-based materials. Applicable Materials: River pebbles, granite, basalt, iron ore, limestone, quartz, diabase, iron ore, gold ore, copper ore, and various ores, rocks, mineral slags, refractory materials, and other minerals.

DHGP220 Single-cylinder Hydraulic Cone Crusher

Product Introduction: The single-cylinder hydraulic cone crusher is a high-capacity single-cylinder hydraulic cone crusher optimized and designed by our company based on the introduction and absorption of European and American technologies. This cone crusher adopts a cavity design with a larger eccentric distance, increased speed, and a greater crushing ratio. It integrates mechanical, hydraulic, electrical, automation, and intelligent control technologies, making it widely applicable for fine, medium, and coarse crushing operations in industries such as metal and non-metallic minerals, cement, sand and gravel, and metallurgy. It features high crushing efficiency, low production costs, easy maintenance and adjustment, and excellent crushed product particle shape. Application Range: Mainly used for crushing raw materials in metallurgy, mining, construction, chemical, and silicate industries. It can be installed on concrete or steel structure foundations and is suitable for fixed or mobile setups. Applicable for large, medium, and small sand and gravel and ore processing enterprises, such as sand and gravel yards, mining operations, coal mining, concrete mixing plants, dry mortar, power plant desulfurization, quartz sand, and other secondary, tertiary, or quaternary crushing of ores, rocks, or rock-based materials. Applicable Materials: River pebbles, granite, basalt, iron ore, limestone, quartz, diabase, iron ore, gold ore, copper ore, and various ores, rocks, mineral slags, refractory materials, and other minerals.

DHGP110 Single-cylinder Hydraulic Cone Crusher

Product Introduction: The single-cylinder hydraulic cone crusher is a high-capacity single-cylinder hydraulic cone crusher designed and manufactured by our company based on the introduction and absorption of European and American technologies. This cone crusher features a larger eccentric distance, increased speed, and a cavity design with a higher crushing ratio. It integrates mechanical, hydraulic, electrical, automation, and intelligent control technologies, making it widely applicable for fine, medium, and coarse crushing operations in industries such as metal and non-metallic minerals, cement, sand and gravel, and metallurgy. It offers advantages such as high crushing efficiency, low production cost, easy maintenance and adjustment, and excellent crushed product particle shape. Application Range: Mainly used for crushing raw materials in metallurgy, mining, construction, chemical, and silicate industries. It can be installed on concrete or steel structure foundations and is suitable for fixed or mobile setups. Applicable for large, medium, and small sand and gravel and ore processing enterprises, such as sand and gravel yards, mining operations, coal mining, concrete mixing plants, dry mortar, power plant desulfurization, quartz sand, and other secondary, tertiary, or quaternary crushing of ores, rocks, or rock-based materials. Applicable Materials: River pebbles, granite, basalt, iron ore, limestone, quartz, diabase, iron ore, gold ore, copper ore, and various ores, rocks, slags, refractory materials, and other minerals.

DHGP550S Single-cylinder Hydraulic Cone Crusher

Product Introduction: The single-cylinder hydraulic cone crusher is a high-capacity single-cylinder hydraulic cone crusher optimized and designed by our company based on the introduction and absorption of European and American technologies. This cone crusher adopts a cavity design with a larger eccentric distance, increased speed, and greater crushing ratio. It integrates mechanical, hydraulic, electrical, automation, and intelligent control technologies, and can be widely used for fine, medium, and coarse crushing operations in industries such as metal and non-metallic minerals, cement, sand and gravel, and metallurgy. It features high crushing efficiency, low production cost, easy maintenance and adjustment, and excellent crushed product particle shape. Application Range: Mainly used for crushing raw materials in metallurgy, mining, construction, chemical, and silicate industries. It can be installed on concrete or steel structure foundations and is suitable for fixed or mobile sites. Applicable to large, medium, and small sand and gravel and ore processing enterprises, such as sand and gravel yards, mining, coal mining, concrete mixing plants, dry mortar, power plant desulfurization, quartz sand, etc., for secondary, tertiary, or quaternary crushing of ores, rocks, or rock-based materials. Applicable Materials: Various minerals such as river pebbles, granite, basalt, iron ore, limestone, quartz, diabase, iron ore, gold ore, copper ore, as well as ores, rocks, slags, refractory materials, and other minerals.

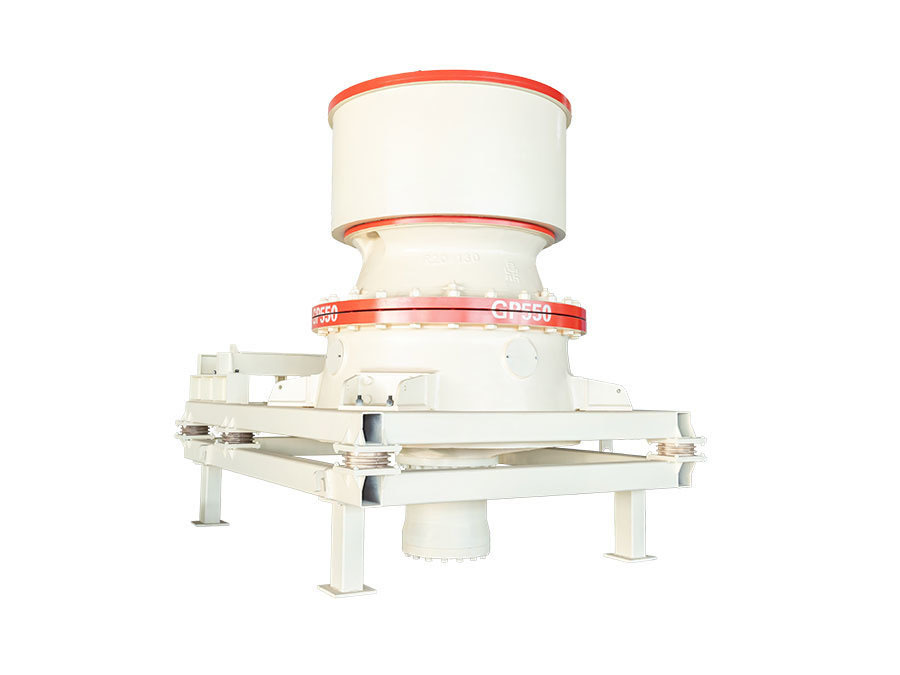

DHGP550 Single-cylinder Hydraulic Cone Crusher

Product Introduction: The single-cylinder hydraulic cone crusher is a high-capacity single-cylinder hydraulic cone crusher designed and manufactured by our company based on the introduction and absorption of European and American technologies, with optimized design. This cone crusher features a larger eccentric distance, increased speed, and a cavity design that enhances the crushing ratio. It integrates mechanical, hydraulic, electrical, automation, and intelligent control technologies, making it widely applicable for fine, medium, and coarse crushing operations in industries such as metal and non-metallic minerals, cement, sand and gravel, and metallurgy. It boasts high crushing efficiency, low production costs, easy maintenance and adjustment, and excellent crushed product particle shape. Application Range: Mainly used for crushing raw materials in metallurgy, mining, construction, chemical, and silicate industries. It can be installed on concrete or steel structure foundations and is suitable for fixed or mobile setups. Applicable for large, medium, and small sand and gravel and ore processing enterprises, such as sand and gravel yards, mining operations, coal mining, concrete mixing plants, dry mortar, power plant desulfurization, quartz sand, and other secondary, tertiary, or quaternary crushing of ores, rocks, or rock-based materials. Applicable Materials: River pebbles, granite, basalt, iron ore, limestone, quartz, diabase, iron ore, gold ore, copper ore, and various ores, rocks, slags, refractory materials, and other minerals.

DHGP330 Single-cylinder Hydraulic Cone Crusher

Product Introduction: The single-cylinder hydraulic cone crusher is a high-capacity single-cylinder hydraulic cone crusher optimized and designed by our company based on the introduction and absorption of European and American technologies. This cone crusher features a larger eccentric distance, increased speed, and a cavity design with a higher crushing ratio. It integrates mechanical, hydraulic, electrical, automation, and intelligent control technologies, making it widely applicable for fine, medium, and coarse crushing operations in industries such as metal and non-metallic minerals, cement, sand and gravel, and metallurgy. It boasts advantages such as high crushing efficiency, low production cost, easy maintenance and adjustment, and excellent crushed product particle shape. Application Range: Mainly used for crushing raw materials in metallurgy, mining, construction, chemical, and silicate industries. It can be installed on concrete or steel structure foundations and is suitable for fixed or mobile setups. Applicable for large, medium, and small sand and gravel and ore processing enterprises, such as sand and gravel yards, mining operations, coal mining, concrete mixing plants, dry mortar, power plant desulfurization, quartz sand, and other secondary, tertiary, or quaternary crushing of ores, rocks, or rock-based materials. Applicable Materials: River pebbles, granite, basalt, iron ore, limestone, quartz, diabase, iron ore, gold ore, copper ore, and various ores, rocks, mineral slags, refractory materials, and other minerals.

Rare Oil Circular Vibrating Screen

Product Introduction: The light oil maintenance-free circular vibrating screen is a high-strength, high-excitation force circular vibrating screen designed by our company based on years of on-site practical experience and the adoption of internationally mature design concepts, optimized according to domestic market conditions. It is an ideal device for handling materials after primary and secondary crushing and can also be used for screening finished materials. Customized multi-layer models of the circular vibrating screen can be made according to different customer needs, and all can be used for dry or wet screening operations. Practice has proven that this circular vibrating screen has reasonable and reliable structure, high screening efficiency, strong excitation force, large processing capacity, low vibration noise, durability, easy maintenance, safe and easy operation and maintenance, and can improve production efficiency. Application Range: Widely used in industries such as sand and gravel aggregates, concrete sand making, dry powder mortar, manufactured sand, power plant desulfurization, quartz sand, metal mining, coal, chemical industry, metallurgy, mining, electric power, construction, building materials, cement, and recycling resources. It is screening equipment for screening and grading various loose minerals or rocks. Applicable Materials: River pebbles, granite, limestone, quartz, coal gangue, basalt, silica, alloy powder, iron ore, kaolin, diabase, calcite, etc. It is also suitable for screening operations of various ores, rocks, and dehydration and desliming.

Product Introduction: The vertical shaft impact crusher is developed by our company through absorbing and introducing German technology and years of practical experience. It is a crusher that can freely select the principle of material-to-material and material-to-metal impact for sand making. It features a unique rotor structure design, wear-resistant material technology, and an optimized crushing speed, perfectly combining professional fine crushing technology with machinery. It is a model of the perfect integration of new technology and new processes. It is the core equipment in the manufactured sand industry. The manufactured sand has a smooth particle shape, uniform particle size, low powder content, and high quality. This new generation crusher aims to improve energy utilization, reduce wear rate, extend maintenance cycles, reduce maintenance time, and increase crushing efficiency. It is energy-saving, has high output, long service life, high energy utilization, excellent product particle shape, easy maintenance, and wide application, meeting the needs of modern sand and gravel production. It can provide high-quality sand and gravel aggregates for highways, high-speed railways, high-rise buildings, municipal construction, hydropower dam construction, and concrete mixing plants. It is an ideal device for artificial sand making and stone shaping. It supports the gradual transition of large sand yards towards large-scale and centralized production. Application Range: Widely used in artificial sand making operations for metal and non-metal ores, metallurgical slag, water conservancy and hydropower, refractory materials, building materials, high-grade highways, railways, sand and gravel yards, concrete sand making, dry powder mortar, manufactured sand, power plant desulfurization, quartz sand, and other industries. Applicable Materials: Suitable for sand making and recycling of various hard and brittle materials such as slag tailings, river pebbles, granite, basalt, iron ore, cobblestones, shale, limestone, dolomite, calcite, quartz, diabase, greenschist, coal, calcium carbide, quartz sand, coal gangue, feldspar, construction waste, concrete aggregates, aluminum vanadium clinker, corundum, and other materials.

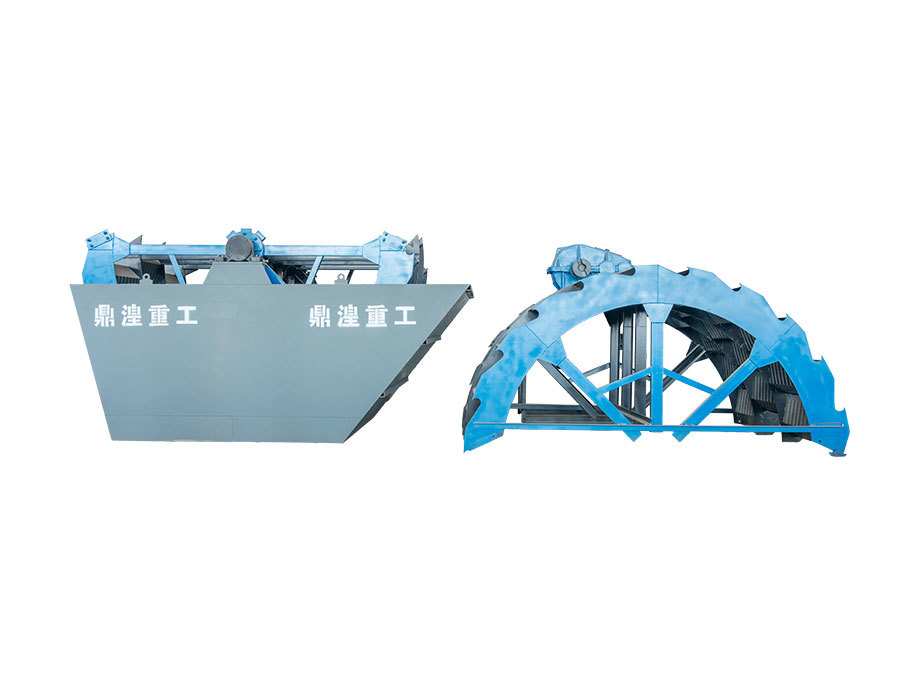

Bucket Wheel Sand Washing Machine

Product Introduction: The wheel sand washing machine is a high-efficiency sand washing equipment developed by our company based on the operational conditions of the sand and gravel industry, using domestic and international technology. It is specially designed for producing high-grade sand and gravel. It is used to clean mud, dust, and other impurities from sand to achieve the purpose of cleaning the sand. It features high cleaning efficiency, large processing capacity, low power consumption, and minimal sand loss. Especially, the transmission parts are isolated from water and sand, greatly reducing the failure rate, making it the preferred choice for upgrading the domestic sand washing industry. Application Scope: Mainly used in metallurgy, building materials, hydropower, and other industries for washing, grading, and impurity removal of fine and coarse materials. Suitable for sand and gravel yards, concrete sand production, dry mortar, manufactured sand, power plant desulfurization, quartz sand, etc. Particularly suitable for construction sand and road-building sand and gravel. Applicable Materials: Quartz sand, limestone, pebbles, river sand, stone powder, granite, basalt, iron ore, calcite, quartzite, diabase, and various natural sand and gravel as well as manufactured sand.

Solution

Choose the right equipment for your industry

Our strong technical force, detection means complete. Products are widely used in mining, building materials, metallurgy, transportation, hydropower, coal, chemical and other industries.

ABOUT US

To build domestic and foreign crushing screening industry quality products

Luoyang Dinghuang Machinery Equipment Co., Ltd. is attached to the Dinghuang Heavy Industry brand. It is a mining machinery manufacturing enterprise that mainly produces crushing and screening machinery, integrating R & D and design, processing and manufacturing, sales and after-sales service. The company is located in the historical and cultural city of Luoyang City, Henan Province.

Since the establishment of the company, on the basis of gradually improving the factory management, it has continued to develop and grow based on the principles of quality assurance, fast time, thoughtful service and reasonable price, and relying on the market. At present, the company covers an area of 20000 square meters and a modern standard factory building of 10000 square meters. There are more than 100 employees, including more than 20 middle and senior technicians. It has more than 60 advanced processing equipment such as 4M gantry machining center, 2.5mm CNC vertical lathe 160 CNC boring machine, and a large number of testing instruments such as material testing machines, ultrasonic flaw detectors and spectrometers, and has established a complete processing technology system and a perfect quality assurance system. Can provide you with various types of machining and machine assembly.

Brand establishment years

Modern standard workshop

On-the-job staff

Sold to countries and regions

innovate

Independent research and development

to technological innovation Build the core competitiveness of Ding Hao

On the basis of introducing and absorbing foreign advanced technology, the company advocates the development concept of "independent innovation and building the core competitiveness of enterprises with technological innovation", and its technical performance is at the excellent level in China. Our company provides satisfactory service for you. Customer support is the driving force for the advancement and development of the enterprise. We will continue to make progress, strive to improve the hardware facilities of the enterprise, and unremittingly pursue excellent technology and excellent quality.

01

Processing capacity

It has more than 60 advanced processing equipment such as 4M gantry machining center, 2.5mm CNC vertical lathe 160 CNC boring machine, and a large number of testing instruments such as material testing machine, ultrasonic flaw detector, spectrometer, etc., and has established a complete processing technology system and a perfect quality assurance system.

02

Process Technology

In the production process, a good market reputation has been established. Professional technicians provide process design for your products, and specialized inspectors provide good quality for you.

03

R & D Team

The modern standard factory building is 10000 square meters; there are more than 100 employees, including more than 20 middle and senior technicians; a group of excellent engineers and senior technical workers have been trained in the development of the company.

04

After-sales service

The company has established a good corporate image among many users with good product quality, thoughtful after-sales service and honest management style.

Gansu Zhongyingji Mining

Shanxi Mingdu Shi Da Shangmao Co., Ltd.

Uzbekistan Chxun Mining

Luanchuan Caiolaowang Mining

Luanchuan Zhongxin Mining

Ximao Mining of Luanchuan County

Luanchuan County Huiton Mining

Longxiang Mining Industry, Lushi County, Sanmenxia City

Luoyang Changxing Jian Mining

Luoyang Cangyi Da Mining

Gansu Zhongyingji Mining

Shanxi Mingdu Shi Da Shangmao Co., Ltd.

Uzbekistan Chxun Mining

Luanchuan Caiolaowang Mining

Luanchuan Zhongxin Mining

Ximao Mining of Luanchuan County

Luanchuan County Huiton Mining

Longxiang Mining Industry, Lushi County, Sanmenxia City

Luoyang Changxing Jian Mining

Luoyang Cangyi Da Mining

Gansu Zhongyingji Mining

Shanxi Mingdu Shi Da Shangmao Co., Ltd.

Uzbekistan Chxun Mining

Luanchuan Caiolaowang Mining

Luanchuan Zhongxin Mining

Ximao Mining of Luanchuan County

Luanchuan County Huiton Mining

Longxiang Mining Industry, Lushi County, Sanmenxia City

Luoyang Changxing Jian Mining

Luoyang Cangyi Da Mining

Pucheng County Mingjiang Construction Co., Ltd.

Luanchuan Xinyuan Mining Co., Ltd.

Da Zheng Investment Co., Ltd., Huizhou

Gansu Zhongyingji Mining

Shanxi Mingdu Shi Da Shangmao Co., Ltd.

Uzbekistan Chxun Mining

Luanchuan Cai Laowang Mining

Luanchuan Zhongxin Mining

Luanchuan County Ximao Mining

Pucheng County Mingjiang Construction Co., Ltd.

Luanchuan Xinyuan Mining Co., Ltd.

Da Zheng Investment Co., Ltd., Huizhou

Gansu Zhongyingji Mining

Shanxi Mingdu Shi Da Shangmao Co., Ltd.

Uzbekistan Chxun Mining

Luanchuan Cai Laowang Mining

Luanchuan Zhongxin Mining

Luanchuan County Ximao Mining

Pucheng County Mingjiang Construction Co., Ltd.

Luanchuan Xinyuan Mining Co., Ltd.

Da Zheng Investment Co., Ltd., Huizhou

Gansu Zhongyingji Mining

Shanxi Mingdu Shi Da Shangmao Co., Ltd.

Uzbekistan Chxun Mining

Luanchuan Cai Laowang Mining

Luanchuan Zhongxin Mining

Luanchuan County Ximao Mining

Luanchuan County Huiton Mining

Longxiang Mining Industry, Lushi County, Sanmenxia City

Luoyang Changxing Jian Mining

Luoyang Cangyi Da Mining

Pucheng County Mingjiang Construction Co., Ltd.

Luanchuan Xinyuan Mining Co., Ltd.

Da Zheng Investment Co., Ltd., Huizhou

Gansu Zhongyingji Mining

Shaanxi Mingdu Shi Da Business Trade Co., Ltd.

Uzbekistan Chxun Mining

Luanchuan County Huiton Mining

Longxiang Mining Industry, Lushi County, Sanmenxia City

Luoyang Changxing Jian Mining

Luoyang Cangyi Da Mining

Pucheng County Mingjiang Construction Co., Ltd.

Luanchuan Xinyuan Mining Co., Ltd.

Da Zheng Investment Co., Ltd., Huizhou

Gansu Zhongyingji Mining

Shaanxi Mingdu Shi Da Business Trade Co., Ltd.

Uzbekistan Chxun Mining

Luanchuan County Huiton Mining

Longxiang Mining Industry, Lushi County, Sanmenxia City

Luoyang Changxing Jian Mining

Luoyang Cangyi Da Mining

Pucheng County Mingjiang Construction Co., Ltd.

Luanchuan Xinyuan Mining Co., Ltd.

Da Zheng Investment Co., Ltd., Huizhou

Gansu Zhongyingji Mining

Shaanxi Mingdu Shi Da Business Trade Co., Ltd.

Uzbekistan Chxun Mining

Luanchuan Caiolaowang Mining

Luanchuan Zhongxin Mining

Luanchuan County Ximao Mining

Luanchuan County Huiton Mining

Longxiang Mining Industry, Lushi County, Sanmenxia City

Longxiang Mining Industry, Lushi County, Sanmenxia City

Luoyang Changxing Jian Mining

Luoyang Cangyi Da Mining

Pucheng County Famous General Construction Co., Ltd.

Luanchuan Xinyuan Mining Co., Ltd.

Luanchuan Caiolaowang Mining

Luanchuan Zhongxin Mining

Luanchuan County Ximao Mining

Luanchuan County Huiton Mining

Longxiang Mining Industry, Lushi County, Sanmenxia City

Longxiang Mining Industry, Lushi County, Sanmenxia City

Luoyang Changxing Jian Mining

Luoyang Cangyi Da Mining

Pucheng County Famous General Construction Co., Ltd.

Luanchuan Xinyuan Mining Co., Ltd.

Luanchuan Caiolaowang Mining

Luanchuan Zhongxin Mining

Luanchuan County Ximao Mining

Luanchuan County Huiton Mining

Longxiang Mining Industry, Lushi County, Sanmenxia City

Longxiang Mining Industry, Lushi County, Sanmenxia City

Luoyang Changxing Jian Mining

Luoyang Cangyi Da Mining

Pucheng County Famous General Construction Co., Ltd.

Luanchuan Xinyuan Mining Co., Ltd.

Da Zheng Investment Co., Ltd., Huizhou

Gansu Zhongyingji Mining

Shanxi Mingdu Shi Da Shangmao Co., Ltd.

Uzbekistan Telecom Mining

Luanchuan Cai Laowang Mining

Luanchuan Zhongxin Mining

Luanchuan County Ximao Mining

Luanchuan County Huiton Mining

Longxiang Mining Industry, Lushi County, Sanmenxia City

Luoyang Changxing Jian Mining

Da Zheng Investment Co., Ltd., Huizhou

Gansu Zhongyingji Mining

Shanxi Mingdu Shi Da Shangmao Co., Ltd.

Uzbekistan Telecom Mining

Luanchuan Cai Laowang Mining

Luanchuan Zhongxin Mining

Luanchuan County Ximao Mining

Luanchuan County Huiton Mining

Longxiang Mining Industry, Lushi County, Sanmenxia City

Luoyang Changxing Jian Mining

Da Zheng Investment Co., Ltd., Huizhou

Gansu Zhongyingji Mining

Shanxi Mingdu Shi Da Shangmao Co., Ltd.

Uzbekistan Telecom Mining

Luanchuan Cai Laowang Mining

Luanchuan Zhongxin Mining

Luanchuan County Ximao Mining

Luanchuan County Huiton Mining

Longxiang Mining Industry, Lushi County, Sanmenxia City

Luoyang Changxing Jian Mining

Luoyang Cangyi Da Mining

Pucheng County Mingjiang Construction Co., Ltd.

Luanchuan Xinyuan Mining Co., Ltd.

Da Zheng Investment Co., Ltd., Huizhou

Gansu Zhongyingji Mining

Shanxi Mingdu Shida Business Co., Ltd.

Uzbekistan Chxun Mining

Luanchuan Cai Laowang Mining

Luanchuan Zhongxin Mining

Luanchuan County Ximao Mining

Luoyang Cangyi Da Mining

Pucheng County Mingjiang Construction Co., Ltd.

Luanchuan Xinyuan Mining Co., Ltd.

Da Zheng Investment Co., Ltd., Huizhou

Gansu Zhongyingji Mining

Shanxi Mingdu Shida Business Co., Ltd.

Uzbekistan Chxun Mining

Luanchuan Cai Laowang Mining

Luanchuan Zhongxin Mining

Luanchuan County Ximao Mining

Luoyang Cangyi Da Mining

Pucheng County Mingjiang Construction Co., Ltd.

Luanchuan Xinyuan Mining Co., Ltd.

Da Zheng Investment Co., Ltd., Huizhou

Gansu Zhongyingji Mining

Shanxi Mingdu Shida Business Co., Ltd.

Uzbekistan Chxun Mining

Luanchuan Cai Laowang Mining

Luanchuan Zhongxin Mining

Luanchuan County Ximao Mining

If you have any requests or questions, please leave a message. We will reply to you as soon as possible after receiving it!

Get your solution

Leave your message, we will provide you with solutions by phone or email to create greater value for customers

Blog

Focus on real-time dynamics of enterprises

Focus on crushing and screening machinery industry solutions

58 Guangshen Road, Luoxin Park, Economic and Technological Development Zone, Xin'an County, Luoyang City, Henan Province

Online message

We will contact you within one working day. Please pay attention to your phone or email.