Mining and ore dressing

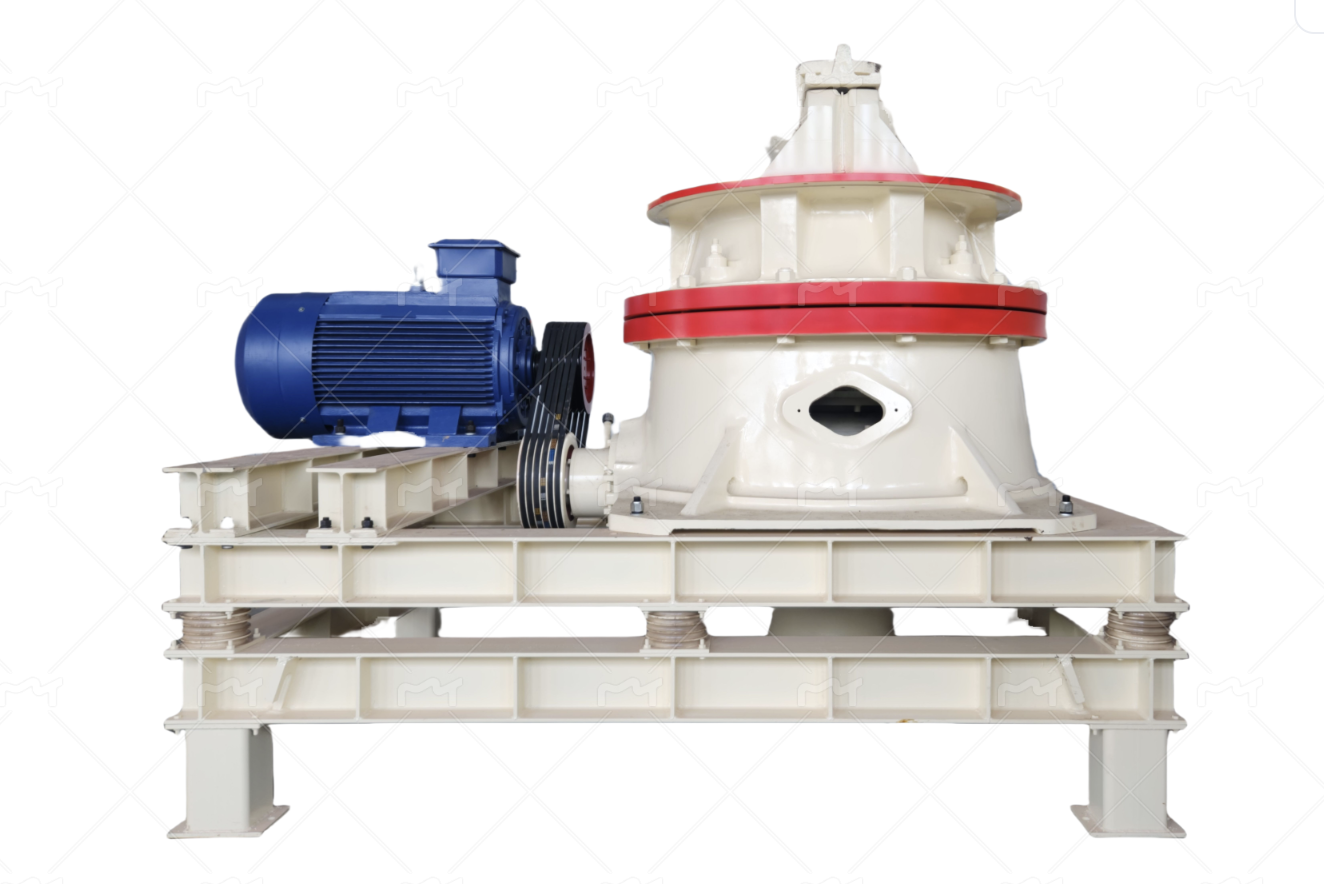

DHGP110 Single-cylinder Hydraulic Cone Crusher

Category:

Product Details

Our Advantages

True versatility

Long-term Performance

Outstanding reliability

Easy to install, use, and maintain

Working Principle

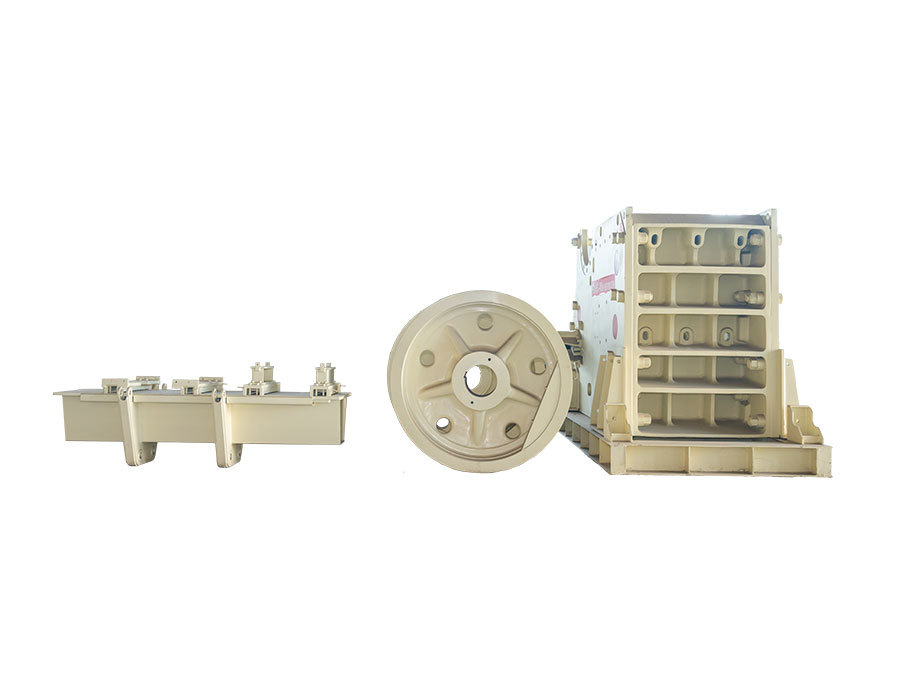

The single-cylinder hydraulic cone crusher mainly consists of the upper frame, middle frame (coarse crushing type), lower frame, moving cone part, eccentric sleeve part, transmission part, hydraulic cylinder part, and other components. When the single-cylinder cone crusher is working, the motor drives the horizontal shaft to rotate, which in turn drives the small gear on the shaft to rotate. The small gear drives the large gear, and the large gear assembly drives the eccentric sleeve assembly and the main shaft assembly to revolve around the theoretical vertical line center inside the copper bushing. The main shaft assembly performs a swinging motion within the eccentric copper sleeve along the centerline of the main shaft. This causes the crushing wall of the cone crusher to approach and move away from the fixed rolling wall surface mounted on the upper frame intermittently, so the ore is continuously impacted and crushed in the crushing chamber, and the crushed material is discharged from the bottom. Adjustment of the discharge opening size: The primary function of the bottom hydraulic cylinder is to adjust the vertical position of the main shaft, thereby adjusting the gap between the moving cone and the outer cone liner. When this gap decreases, the crusher's discharge particle size becomes smaller; when the gap increases, the discharge particle size becomes larger. Additionally, selecting different crushing chamber types and different eccentricities can also change the size of the discharged material.

Material enters the crushing wall through the upper feed hopper. Under the resistance of the material, the main shaft assembly slowly swings within the eccentric copper sleeve, completing the crushing action between the crushing wall and the rolling mortar wall. The running trajectory of the inner cone appears to swing back and forth inside the crushing chamber while slowly rotating. The material is crushed by the oscillating inner cone and then discharged through the outlet. Feed and discharge hoppers collect the material.

The single-cylinder hydraulic cone crusher has advantages such as high output, low operating cost, compact structure, simple operation, low maintenance, wide applicability, and high utilization rate.

Advantages and Features

Selectable crushing chamber types, reasonable eccentricity and stroke frequency, and laminated crushing bring higher output, greater crushing ratio, and better product particle shape.

Robust equipment structure and advanced overload protection system ensure long-term operation in the harshest hard rock crushing applications with low failure rates.

The positive pressure dust prevention system ensures the lubrication system remains clean at all times. The internal pressure of the crushing chamber is always higher than the external pressure, preventing dust contamination during operation, protecting bearings, and eliminating the need for additional lubrication seals and manual maintenance. The thin oil lubrication system provides dual protection for the bearings; effectively reducing failure rates, extending the crusher's service life, and reducing maintenance workload and costs.

High degree of automation and simple operation allow even ordinary operators to quickly master the equipment. Maintenance is convenient, with most parts removable from the top and sides, reducing labor intensity and improving construction efficiency.

Structural upgrades provide higher safety. Transmission components use imported bearings with longer life and lower production costs. Eccentric crushing and full feeding increase equipment operating rate.

Stepless adjustment of the discharge opening can be achieved by hydraulic pressure with just button control, and can be done during production, making operation more intuitive. After precision machining, wear parts require no packing during assembly.

The cone crusher uses a PLC fully automatic control system to ensure safe operation. It allows simple operation and control of the crusher, with high visualization, reducing user operation difficulty and labor costs.

Special designs of the crushing wall and rolling mortar wall increase the utilization rate of wear parts, extend liner service life, and greatly reduce user investment in spare parts.

The brand-new intelligent system can trace all operating data, quickly complete parameter optimization, fault handling, and maintenance. The structure is simple, reliable, easy to maintain, with low operating costs, faster and more convenient replacement, and reduced downtime. The upper, (middle), and lower frames and main shaft are reinforced, significantly improving equipment reliability; enhanced frame structure design with key parts inspected by non-destructive testing ensures higher body strength and more reliable operation.

Integrated design of hydraulic station and lubrication station saves installation space; the hydraulic system is designed with high pressure to meet ordinary pressure requirements, providing higher pressure margin during operation and improving hydraulic system reliability.

Technical Parameters

Specifications and Models | Cone Crusher Chamber Type | Maximum Feed Size (mm) | Capacity (t/h) at Tight Side Discharge Opening Size (mm) | |||||||||||||||||||

8mm | 12mm | 16mm | 20mm | 24mm | 25mm | 28mm | 30mm | 32mm | 35mm | 36mm | 40mm | 45mm | 50mm | 55mm | 60mm | 65mm | 70mm | 75mm | 80mm | |||

DHGP100 | Z | 0-150 |

|

|

|

|

| 115-125 |

| 140-150 |

| 155-175 |

| 165-195 | 180-210 |

|

|

|

|

|

|

|

DHGP100S | C | 0-250 |

|

|

|

|

|

|

| 180-190 |

| 195-215 |

| 205-225 |

|

|

|

|

|

|

|

|

DHGP220 | X | 0-80 |

| 80-100 | 100-150 | 120-180 |

| 150-210 |

| 180-205 |

|

|

|

|

|

|

|

|

|

|

|

|

Z | 0-200 |

|

|

|

|

|

|

| 165-215 |

| 185-235 |

| 205-255 | 225-275 |

|

|

|

|

|

|

| |

DHGP220S | C | 0-300 |

|

|

|

|

|

|

|

|

| 225-275 |

| 265-315 | 275-345 |

|

|

|

|

|

|

|

DHGP330 | X | 0-80 | 100-130 | 120-190 | 140-240 | 160-270 | 180-310 |

| 200-340 |

| 220-360 |

| 240-330 |

|

|

|

|

|

|

|

|

|

Z | 0-240 |

|

|

|

|

| 170-190 |

| 170-210 |

| 190-410 |

| 210-500 | 230-520 | 260-295 |

|

|

|

|

|

| |

DHGP330S | C | 0-350 |

|

|

|

|

|

|

| 280-450 |

| 320-500 |

| 340-490 |

|

|

|

|

|

|

|

|

DHGP550 | X | 0-100 | 150-170 | 160-250 | 190-280 | 230-350 | 250-400 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Z | 0-250 |

|

|

|

|

|

|

|

|

|

|

|

| 300-350 | 320-700 | 370-750 | 400-950 | 420-1050 | 450-950 | 500-1000 | 550-600 | |

DHGP550S | C | 0-500 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DHGP760 | X | 0-120 |

| 230-384 | 265-447 | 280-440 | 300-460 | 343-502 |

|

| 362-552 |

|

|

|

|

|

|

|

|

|

|

|

Z | 0-200 |

|

| 185-350 | 240-485 | 250-500 | 285-565 |

|

| 321-615 |

| 340-590 |

| 365-625 |

|

|

|

|

|

|

| |

| Note: X = fine crushing cavity type, Z = medium crushing cavity type, C = coarse crushing cavity type | ||||||||||||||||||||||

Application Range

Applicable materials

Next page: DHGP220 Single-cylinder Hydraulic Cone Crusher

Related Products

Mainly producing crushing and screening machinery, integrating R&D design, processing and manufacturing, sales, and after-sales service as a mining machinery manufacturing enterprise.

Related Products

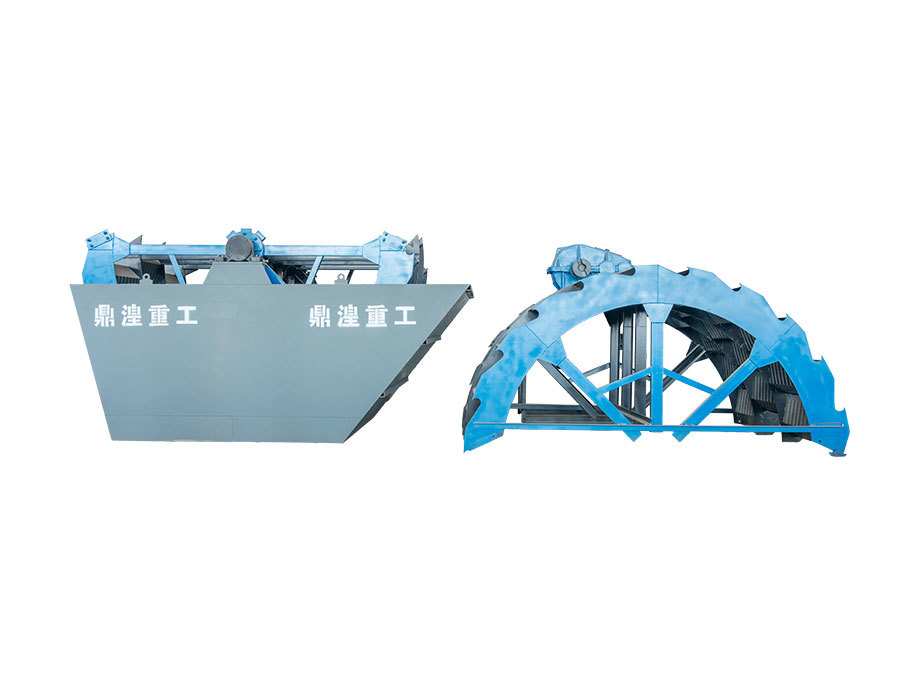

Feeder

-

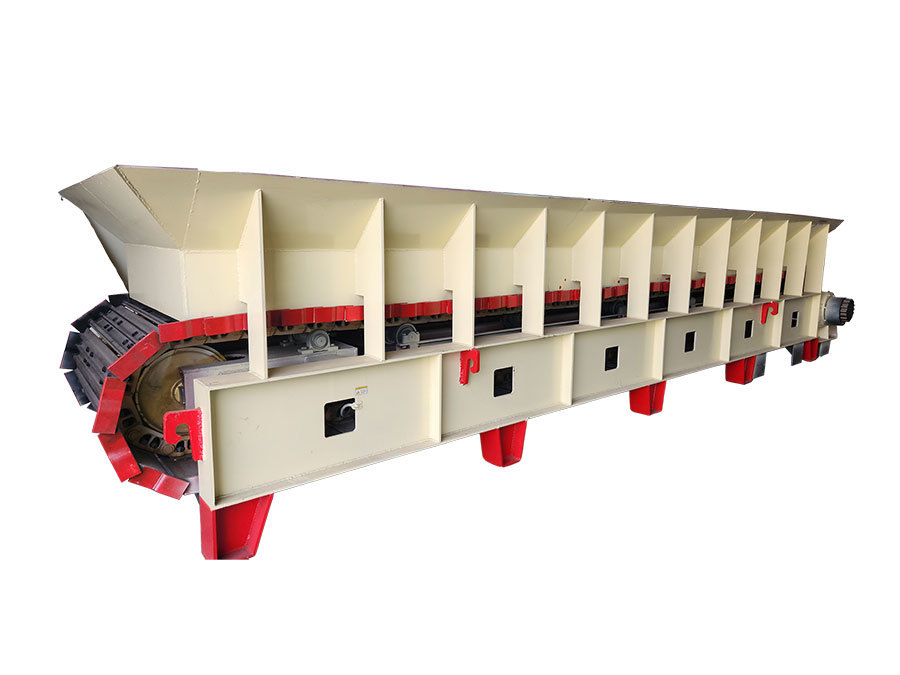

Flat chain feeder

Product Introduction: The feeder is a new type of feeder independently developed and designed by our company based on years of experience in design, production, sales, and service in the mining industry, combined with the development of modern industrial technology and extensive absorption of foreign technology. It is mainly used for continuous and uniform feeding before crushers, capable of evenly, timely, and continuously conveying block and granular materials to crushing machinery. It features a compact structure and strong impact resistance, greatly optimizing the particle size of materials entering the crusher, improving crusher capacity, and reducing energy consumption. It can meet harsh initial feeding conditions such as high bunker pressure, heavy load, and large impact. It is a highly efficient material supply device. Application Range: Widely used in crushing and screening combined equipment in industries such as sand and gravel aggregates, metallurgy, mining, coal mining, mineral processing, cement, construction, building materials, chemical industry, abrasives, refractory materials, and ceramics. Applicable Materials: River pebbles, cobblestones, iron ore, marble, dolomite, coal gangue, quartz, barite, granite, diabase, basalt, iron ore, gold ore, feldspar, silica, calcite, limestone, talc, gypsum, bentonite, and other ores, rocks, and slag materials.

-

Plate Feeder

Product Introduction: The feeder is a new type of feeder independently developed and designed by our company based on years of experience in design, production, sales, and service in the mining industry, combined with the development of modern industrial technology and extensive absorption of foreign technology. It is mainly used for continuous and uniform feeding before crushers, capable of evenly, timely, and continuously conveying block and granular materials to crushing machinery. It features a compact structure and strong impact resistance, greatly optimizing the particle size of materials entering the crusher, improving crusher capacity, and reducing energy consumption. It can meet harsh initial feeding conditions such as high silo pressure, heavy load, and large impact. It is a highly efficient material supply device. Application Range: Widely used in crushing and screening combined equipment in industries such as sand and gravel aggregates, metallurgy, mining, coal mining, mineral processing, cement, construction, building materials, chemical industry, abrasives, refractory materials, and ceramics. Applicable Materials: River pebbles, cobblestones, iron ore, marble, dolomite, coal gangue, quartz, barite, granite, diabase, basalt, iron ore, gold ore, feldspar, silica, calcite, limestone, talc, gypsum, bentonite, and other ores, rocks, and slag materials.

-

Stick Feeder

Product Introduction: The feeder is a new type of feeder independently developed and designed by our company based on years of experience in design, production, sales, and service in the mining industry, combined with the development of modern industrial technology and extensive absorption of foreign technology. It is mainly used for continuous and uniform feeding before crushers, capable of evenly, timely, and continuously conveying block and granular materials to crushing machinery. It features a compact structure and strong impact resistance, greatly optimizing the particle size of materials entering the crusher, improving crusher capacity, and reducing energy consumption. It can meet harsh initial feeding conditions such as high silo pressure, heavy load, and large impact. It is a highly efficient material supply device. Application Range: Widely used in crushing and screening combined equipment in industries such as sand and gravel aggregates, metallurgy, mining, coal mining, mineral processing, cement, construction, building materials, chemical industry, abrasives, refractory materials, and ceramics. Applicable Materials: River pebbles, cobblestones, iron ore, marble, dolomite, coal gangue, quartz, barite, granite, diabase, basalt, iron ore, gold ore, feldspar, silica, calcite, limestone, talc, gypsum, bentonite, and other ores, rocks, and slag materials.

European Version Jaw Crusher

-

DHC-96 European Version Jaw Crusher

Product Introduction: The European version jaw crusher is a new type of European jaw crusher developed by our company based on the introduction and absorption of foreign jaw crusher technology, combined with decades of accumulated jaw crusher design concepts and technology. It is optimized and manufactured from multiple aspects including structure, material selection, process, and assembly. It features a unique structure and superior performance, making it an ideal equipment for coarse crushing of hard and highly abrasive ores and rocks. It has specially designed features such as a detachable, weld-free frame structure, optimized cavity structure, double wedge block adjustment device, selected raw materials and components, elastic limit shock absorption device, and integrated motor base. It offers high crushing efficiency, low investment cost, long service life, and stability, thereby meeting different working conditions, reducing the tonnage cost of material crushing, and satisfying customer expectations. The European version jaw crusher is a crushing equipment favored by the market. Application Range: Widely used in mining, sand and gravel yards, cement plants, road construction, metallurgy, chemical industry, construction, refractory materials, ceramics, and other industrial sectors. Also applicable to sand and gravel yards, mining, coal mining, concrete mixing plants, dry mortar, power plant desulfurization, quartz sand, etc. Applicable Materials: Granite, marble, pebble, dolomite, limestone, cobblestone, gold ore, basalt, quartz, river pebble, iron ore, diabase, iron ore, gold ore, copper ore, ore, rock, slag, etc.

-

DHC-100 European Version Jaw Crusher

Product Introduction: The European version jaw crusher is a new type of European jaw crusher developed by our company based on the introduction and absorption of foreign jaw crusher technology, combined with decades of accumulated jaw crusher design concepts and technology. It is optimized and manufactured from multiple aspects including structure, material selection, process, and assembly. It features a unique structure and superior performance, making it an excellent choice for coarse crushing of hard and highly abrasive ores and rocks. It has specially designed features such as a detachable, weld-free frame structure, optimized cavity structure, double wedge adjustment device, selected raw materials and components, elastic limit shock absorption device, and integrated motor base. It offers high crushing efficiency, low investment cost, long service life, and stability, meeting different working conditions. It reduces the tonnage cost of material crushing, meets customer expectations, and fills market gaps. The European version jaw crusher is a crushing equipment highly favored by the market. Application Range: Widely used in mining, sand and gravel plants, cement plants, road construction, metallurgy, chemical industry, construction, refractory materials, ceramics, and other industrial sectors. Also suitable for sand and gravel yards, mining, coal mining, concrete mixing plants, dry mortar, power plant desulfurization, quartz sand, etc. Applicable Materials: Granite, marble, pebble, dolomite, limestone, cobblestone, gold ore, basalt, quartz, river pebble, iron ore, diabase, iron ore, gold ore, copper ore, ore, rock, slag, etc.

-

DHC-125 European Version Jaw Crusher

Product Introduction: The European version jaw crusher is a new type of European jaw crusher developed by our company based on the introduction and absorption of foreign jaw crusher technology, combined with decades of accumulated jaw crusher design concepts and technology. It is optimized and manufactured from multiple aspects including structure, material selection, process, and assembly. It features a unique structure and superior performance, making it an excellent choice for coarse crushing of hard and highly abrasive ores and rocks. It has specially designed features such as a detachable, weld-free frame, optimized cavity structure, double wedge adjustment device, selected raw materials and components, elastic limit shock absorption device, and integrated motor base. It offers high crushing efficiency, low investment cost, long service life, and stability, meeting different working conditions. It reduces the tonnage cost of material crushing, meets customer expectations, and fills market gaps. The European version jaw crusher is a crushing equipment highly favored by the market. Application Range: Widely used in mining, sand and gravel plants, cement plants, road construction, metallurgy, chemical industry, construction, refractory materials, ceramics, and other industrial sectors. Also suitable for sand and gravel yards, mining, coal mining, concrete mixing plants, dry mortar, power plant desulfurization, quartz sand, etc. Applicable Materials: Granite, marble, pebble, dolomite, limestone, cobblestone, gold ore, basalt, quartz, river pebble, iron ore, diabase, iron ore, gold ore, copper ore, ore, rock, slag, etc.

-

DHC-145 European Version Jaw Crusher

Product Introduction: The European version jaw crusher is a new type of European jaw crusher developed by our company based on the introduction and absorption of foreign jaw crusher technology, combined with decades of accumulated jaw crusher design concepts and technology. It is optimized and manufactured from multiple aspects including structure, material selection, process, and assembly. It features a unique structure and superior performance, making it an ideal equipment for coarse crushing of various hard and highly abrasive ores and rocks. It has specially designed features such as a detachable, weld-free frame structure, optimized cavity structure, double wedge adjustment device, selected raw materials and components, elastic limit shock absorption device, and integrated motor base. It offers high crushing efficiency, low investment cost, long service life, and stability, thereby meeting different working conditions. It reduces the tonnage cost of material crushing, meets customer expectations, and fills market gaps. The European version jaw crusher is a crushing equipment highly favored by the market. Application Range: Widely used in mining, sand and gravel yards, cement plants, road construction, metallurgy, chemical industry, construction, refractory materials, ceramics, and other industrial sectors. Also applicable to sand and gravel yards, mining, coal mining, concrete mixing plants, dry mortar, power plant desulfurization, quartz sand, etc. Applicable Materials: Granite, marble, pebble, dolomite, limestone, cobblestone, gold ore, basalt, quartz, river pebble, iron ore, diabase, iron ore, gold ore, copper ore, ore, rock, slag, etc.

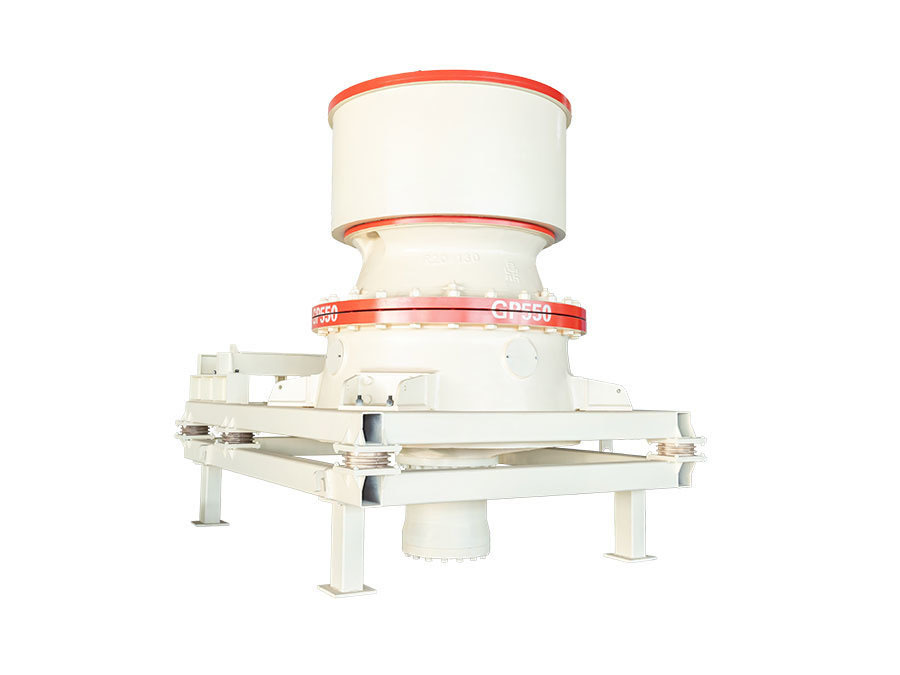

Single-cylinder hydraulic cone crusher

-

DHGP110 Single-cylinder Hydraulic Cone Crusher

Product Introduction: The single-cylinder hydraulic cone crusher is a high-capacity single-cylinder hydraulic cone crusher designed and manufactured by our company based on the introduction and absorption of European and American technologies. This cone crusher features a larger eccentric distance, increased speed, and a cavity design with a higher crushing ratio. It integrates mechanical, hydraulic, electrical, automation, and intelligent control technologies, making it widely applicable for fine, medium, and coarse crushing operations in industries such as metal and non-metallic minerals, cement, sand and gravel, and metallurgy. It offers advantages such as high crushing efficiency, low production cost, easy maintenance and adjustment, and excellent crushed product particle shape. Application Range: Mainly used for crushing raw materials in metallurgy, mining, construction, chemical, and silicate industries. It can be installed on concrete or steel structure foundations and is suitable for fixed or mobile setups. Applicable for large, medium, and small sand and gravel and ore processing enterprises, such as sand and gravel yards, mining operations, coal mining, concrete mixing plants, dry mortar, power plant desulfurization, quartz sand, and other secondary, tertiary, or quaternary crushing of ores, rocks, or rock-based materials. Applicable Materials: River pebbles, granite, basalt, iron ore, limestone, quartz, diabase, iron ore, gold ore, copper ore, and various ores, rocks, slags, refractory materials, and other minerals.

-

DHGP220 Single-cylinder Hydraulic Cone Crusher

Product Introduction: The single-cylinder hydraulic cone crusher is a high-capacity single-cylinder hydraulic cone crusher optimized and designed by our company based on the introduction and absorption of European and American technologies. This cone crusher adopts a cavity design with a larger eccentric distance, increased speed, and a greater crushing ratio. It integrates mechanical, hydraulic, electrical, automation, and intelligent control technologies, making it widely applicable for fine, medium, and coarse crushing operations in industries such as metal and non-metallic minerals, cement, sand and gravel, and metallurgy. It features high crushing efficiency, low production costs, easy maintenance and adjustment, and excellent crushed product particle shape. Application Range: Mainly used for crushing raw materials in metallurgy, mining, construction, chemical, and silicate industries. It can be installed on concrete or steel structure foundations and is suitable for fixed or mobile setups. Applicable for large, medium, and small sand and gravel and ore processing enterprises, such as sand and gravel yards, mining operations, coal mining, concrete mixing plants, dry mortar, power plant desulfurization, quartz sand, and other secondary, tertiary, or quaternary crushing of ores, rocks, or rock-based materials. Applicable Materials: River pebbles, granite, basalt, iron ore, limestone, quartz, diabase, iron ore, gold ore, copper ore, and various ores, rocks, mineral slags, refractory materials, and other minerals.

-

DHGP330 Single-cylinder Hydraulic Cone Crusher

Product Introduction: The single-cylinder hydraulic cone crusher is a high-capacity single-cylinder hydraulic cone crusher optimized and designed by our company based on the introduction and absorption of European and American technologies. This cone crusher features a larger eccentric distance, increased speed, and a cavity design with a higher crushing ratio. It integrates mechanical, hydraulic, electrical, automation, and intelligent control technologies, making it widely applicable for fine, medium, and coarse crushing operations in industries such as metal and non-metallic minerals, cement, sand and gravel, and metallurgy. It boasts advantages such as high crushing efficiency, low production cost, easy maintenance and adjustment, and excellent crushed product particle shape. Application Range: Mainly used for crushing raw materials in metallurgy, mining, construction, chemical, and silicate industries. It can be installed on concrete or steel structure foundations and is suitable for fixed or mobile setups. Applicable for large, medium, and small sand and gravel and ore processing enterprises, such as sand and gravel yards, mining operations, coal mining, concrete mixing plants, dry mortar, power plant desulfurization, quartz sand, and other secondary, tertiary, or quaternary crushing of ores, rocks, or rock-based materials. Applicable Materials: River pebbles, granite, basalt, iron ore, limestone, quartz, diabase, iron ore, gold ore, copper ore, and various ores, rocks, mineral slags, refractory materials, and other minerals.

-

DHGP330S Single-cylinder Hydraulic Cone Crusher

Product Introduction: The single-cylinder hydraulic cone crusher is a high-capacity single-cylinder hydraulic cone crusher optimized and designed by our company based on the introduction and absorption of European and American technologies. This cone crusher features a larger eccentric distance, increased speed, and a cavity design with a higher crushing ratio. It integrates mechanical, hydraulic, electrical, automation, and intelligent control technologies, making it widely applicable for fine, medium, and coarse crushing operations in industries such as metal and non-metallic minerals, cement, sand and gravel, and metallurgy. It boasts advantages such as high crushing efficiency, low production cost, easy maintenance and adjustment, and excellent crushed product particle shape. Application Range: Mainly used for crushing raw materials in metallurgy, mining, construction, chemical, and silicate industries. It can be installed on concrete or steel structure foundations and is suitable for fixed or mobile setups. Applicable for large, medium, and small sand and gravel and ore processing enterprises, such as sand and gravel yards, mining operations, coal mining, concrete mixing plants, dry mortar, power plant desulfurization, quartz sand, and other secondary, tertiary, or quaternary crushing of ores, rocks, or rock-based materials. Applicable Materials: River pebbles, granite, basalt, iron ore, limestone, quartz, diabase, iron ore, gold ore, copper ore, and various ores, rocks, mineral slags, refractory materials, and other minerals.

-

DHGP550 Single-cylinder Hydraulic Cone Crusher

Product Introduction: The single-cylinder hydraulic cone crusher is a high-capacity single-cylinder hydraulic cone crusher designed and manufactured by our company based on the introduction and absorption of European and American technologies, with optimized design. This cone crusher features a larger eccentric distance, increased speed, and a cavity design that enhances the crushing ratio. It integrates mechanical, hydraulic, electrical, automation, and intelligent control technologies, making it widely applicable for fine, medium, and coarse crushing operations in industries such as metal and non-metallic minerals, cement, sand and gravel, and metallurgy. It boasts high crushing efficiency, low production costs, easy maintenance and adjustment, and excellent crushed product particle shape. Application Range: Mainly used for crushing raw materials in metallurgy, mining, construction, chemical, and silicate industries. It can be installed on concrete or steel structure foundations and is suitable for fixed or mobile setups. Applicable for large, medium, and small sand and gravel and ore processing enterprises, such as sand and gravel yards, mining operations, coal mining, concrete mixing plants, dry mortar, power plant desulfurization, quartz sand, and other secondary, tertiary, or quaternary crushing of ores, rocks, or rock-based materials. Applicable Materials: River pebbles, granite, basalt, iron ore, limestone, quartz, diabase, iron ore, gold ore, copper ore, and various ores, rocks, slags, refractory materials, and other minerals.

-

DHGP550S Single-cylinder Hydraulic Cone Crusher

Product Introduction: The single-cylinder hydraulic cone crusher is a high-capacity single-cylinder hydraulic cone crusher optimized and designed by our company based on the introduction and absorption of European and American technologies. This cone crusher adopts a cavity design with a larger eccentric distance, increased speed, and greater crushing ratio. It integrates mechanical, hydraulic, electrical, automation, and intelligent control technologies, and can be widely used for fine, medium, and coarse crushing operations in industries such as metal and non-metallic minerals, cement, sand and gravel, and metallurgy. It features high crushing efficiency, low production cost, easy maintenance and adjustment, and excellent crushed product particle shape. Application Range: Mainly used for crushing raw materials in metallurgy, mining, construction, chemical, and silicate industries. It can be installed on concrete or steel structure foundations and is suitable for fixed or mobile sites. Applicable to large, medium, and small sand and gravel and ore processing enterprises, such as sand and gravel yards, mining, coal mining, concrete mixing plants, dry mortar, power plant desulfurization, quartz sand, etc., for secondary, tertiary, or quaternary crushing of ores, rocks, or rock-based materials. Applicable Materials: Various minerals such as river pebbles, granite, basalt, iron ore, limestone, quartz, diabase, iron ore, gold ore, copper ore, as well as ores, rocks, slags, refractory materials, and other minerals.

No relevant data available, please add in the backend!

Online Message

*You can submit your contact information and product requirements to us, and we will provide you with a detailed one-stop solution. Thank you! To contact you promptly, please be sure to fill in your contact information and requirements completely.

Focus on crushing and screening machinery industry solutions

58 Guangshen Road, Luoxin Park, Economic and Technological Development Zone, Xin'an County, Luoyang City, Henan Province

Online message

We will contact you within one working day. Please pay attention to your phone or email.